Choosing a printing technique for custom T-shirt printing business

Some of us have ever used paid printing services to get a custom T-shirt with a desirable print. But are there many people who have ever thought about starting their own custom T-shirt printing business? If you are one of them, you should know about the existence of different printing techniques, their advantages, and disadvantages. This article is written to help you choose a printing technique which suits your business best of all.

1. Screen printing (silkscreen, serigraph printing) is the traditional way to print your own T-shirts. This method supposes the usage of stencils (screens) which are pressed up against the cloth to force ink onto the material with mesh surface. Only one color at a time is applied, so, it's necessary to create a separate stencil for every color. It's possible to screen print only vector artwork.

Advantages: Screenprints have high quality, they are durable and professional looking. Screen printing allows you to print onto light as well as dark garments.

Disadvantages: It's not the cleanest procedure, you have to create a separate screen for each color. The only cotton material can be used. This method is good and cost-effective for a large volume of products with one design and successfully used for big production. It's not worth trying if you need to do an individual custom order. You need a place to locate the screen printing equipment. Besides, this technique requires learning.

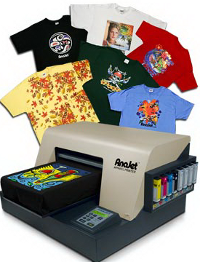

2. Direct to Garment printing (DTG printing, DTS printing - Direct To Shirt printing). It's a modern way to do t-shirt design printing. You need to buy a special inject printer which prints directly onto your garment (t-shirts, mouse pads, caps etc.). This method is very good for individual orders such as custom T-shirt designs. High-resolution raster image (for example .png) is usually enough for DTG printing.

Advantages: Fast and simple process, you get quality, colorful, good-looking photo-like print.

Disadvantages: Good for light T-shirts but difficult to get a quality print on black garments (you need a DTG printer that is specially designed to print on both light and dark shirts). Good DTG machines are expensive, the cost starts from $11,000 to over $200,000 depending on their print size, production capability as well as the model. Most of DTG printers print only on 100% cotton or cotton-blend fabrics. You will have to clean some printing elements of this printer often, otherwise, you may find printing defects on t-shirts.

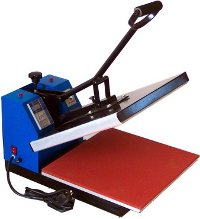

3. Heat transfer printing supposes printing an image on a special heat transfer paper and then transferring a printed image onto a surface by applying pressure and heat. You will need to get a usual inject or laser printer, heat press, heat transfer paper for the type of printer that you are using. This method is also good for small runs and custom orders. Inject heat transfers are limited to cotton, 50/50 poly-cotton, and other cotton blend fabrics.

Advantages: The process is fast, it's affordable at price and therefore profitable. It's easy to print multicolor images (for example photos). Many items that are difficult to screen print may be done with injecting heat transfers - mouse pads, puzzles, bags, flags, etc.

Disadvantages: Print may have a heavy look, it fades and cracks with time, especially on dark t-shirts. But it is claimed to be some new good equipment which coped with this disadvantage.

Also, there is a recommendation to use quality ink, quality transfer paper to get quality product as lasting as screen printed. Besides, if you use heat transfer printing, always give your customers t-shirt care information such as Wash the garment inside out, Cold wash, Hand dry.

4. Vinyl heat transfer printing. Again this technique is good for printing your own t-shirts when you have a small volume of individual orders. You need to use a special vinyl cutter which cuts letters or numbers or segments of an image from a vinyl film which is one-color only. After that, heat press glues a cut item onto the garment.

Advantages: You get quality artwork, durable and stable. This method is cost-effective and works on both light and dark garments.

Disadvantages: You need to cut each color separately that's why too time-consuming for making multi-color prints (don't even try to do photos). This method is only good for applying simple signs and vector images.

5. Dye sublimation printing is a popular technique which is good for printing individual orders of a customer. You will need to acquire a printer which comfortably works with sublimation ink and a heat press. Sublimation printing and heat transfer are often confused. Both methods suppose the usage of heat presses to “transfer” the image to the material. The main difference is the actual transfer process. Dye sublimation uses a gaseous process which is then triggered by the heat press.

Advantages: You get a good-looking, bright print on light-colored materials. It's possible to do sublimation on non-textile products such as mugs, mouse pads, plates, business card holders, name badges, coasters, etc. It has a soft feeling it doesn't fade or crack.

Disadvantages: It works on polymer materials only (polyester t-shirts). Sublimation ink is rather expensive. This method is not suitable for dark colored garments.

Once the printer is chosen, you only need to purchase sole-colored T-shirts to print on.

The best way to sell customizable T-shirts is through an online store, it's great if you have one. If you are just considering to open your online custom T-shirt business where you will both sell customizable t-shirts and print orders, you will need to find a good shopping cart platform with design tool for your customers. We may offer you affordable at price fully-featured Product design software. It is a ready-to-use solution which allows you to build a powerful online store with a possibility for customers to personalize products.

You may be interested in